The printer is a Voron 2.4, the extruder is a StealthBurner, and the hot end itself is a Rapido MK1. I’m printing Polymaker ASA on a spool that hasn’t given me any grief thus far (I last printed with it a few days ago) and am slicing with Orca Slicer.

The printer has about 700 hours on it. In that time, I’ve run 4.1 km of filament through it. These two prints are two of the three jams I’ve experienced in that time span. The first print failed on a very similar feature (internal bridge), but on a much much much smaller print. I’ve printed some pretty long (> 12 hour) parts on this printer with the same brand of filament, and similar settings, without issues although this is the first large “fairly normal polygon with big parallel faces” that I’ve tried to print.

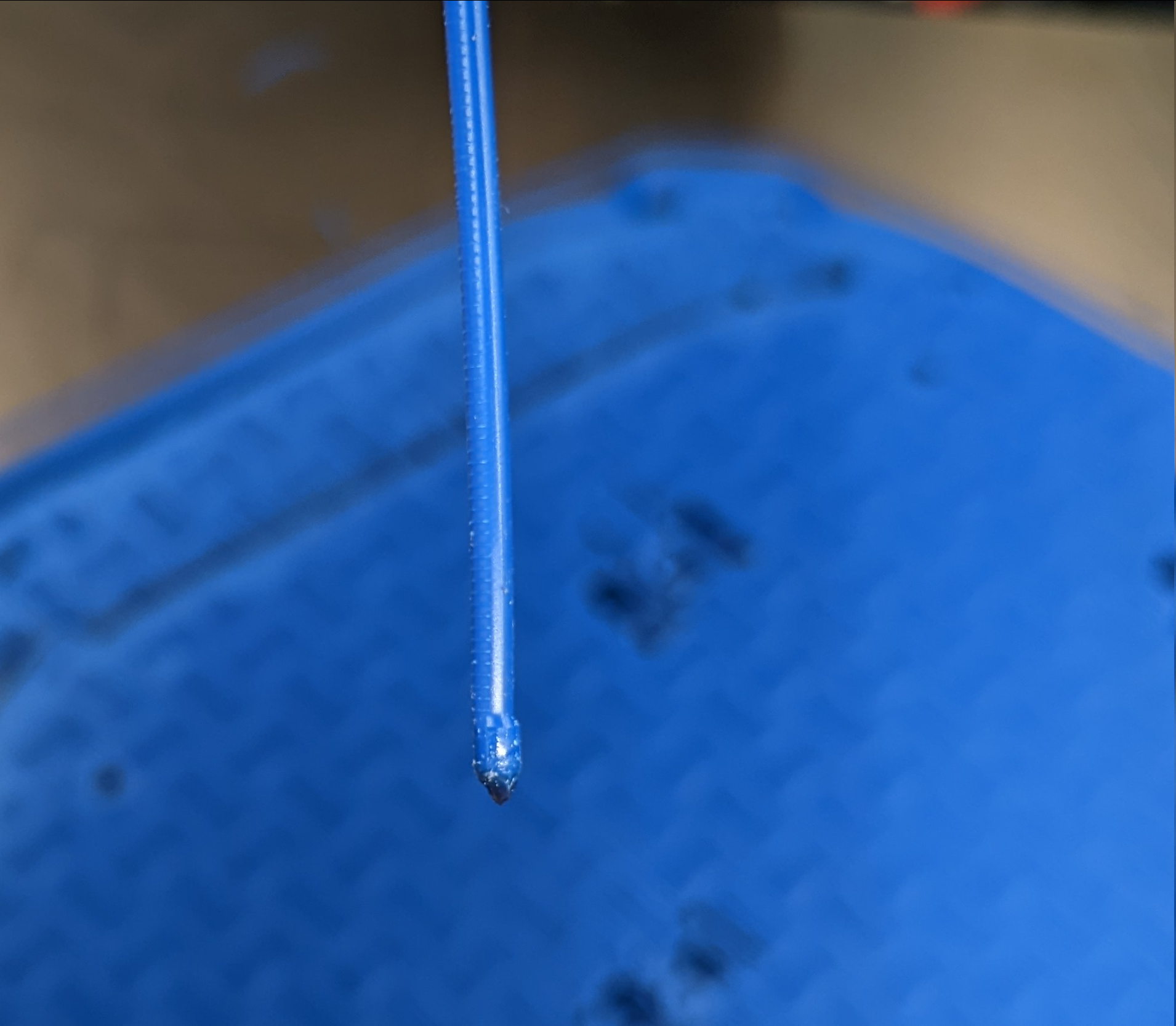

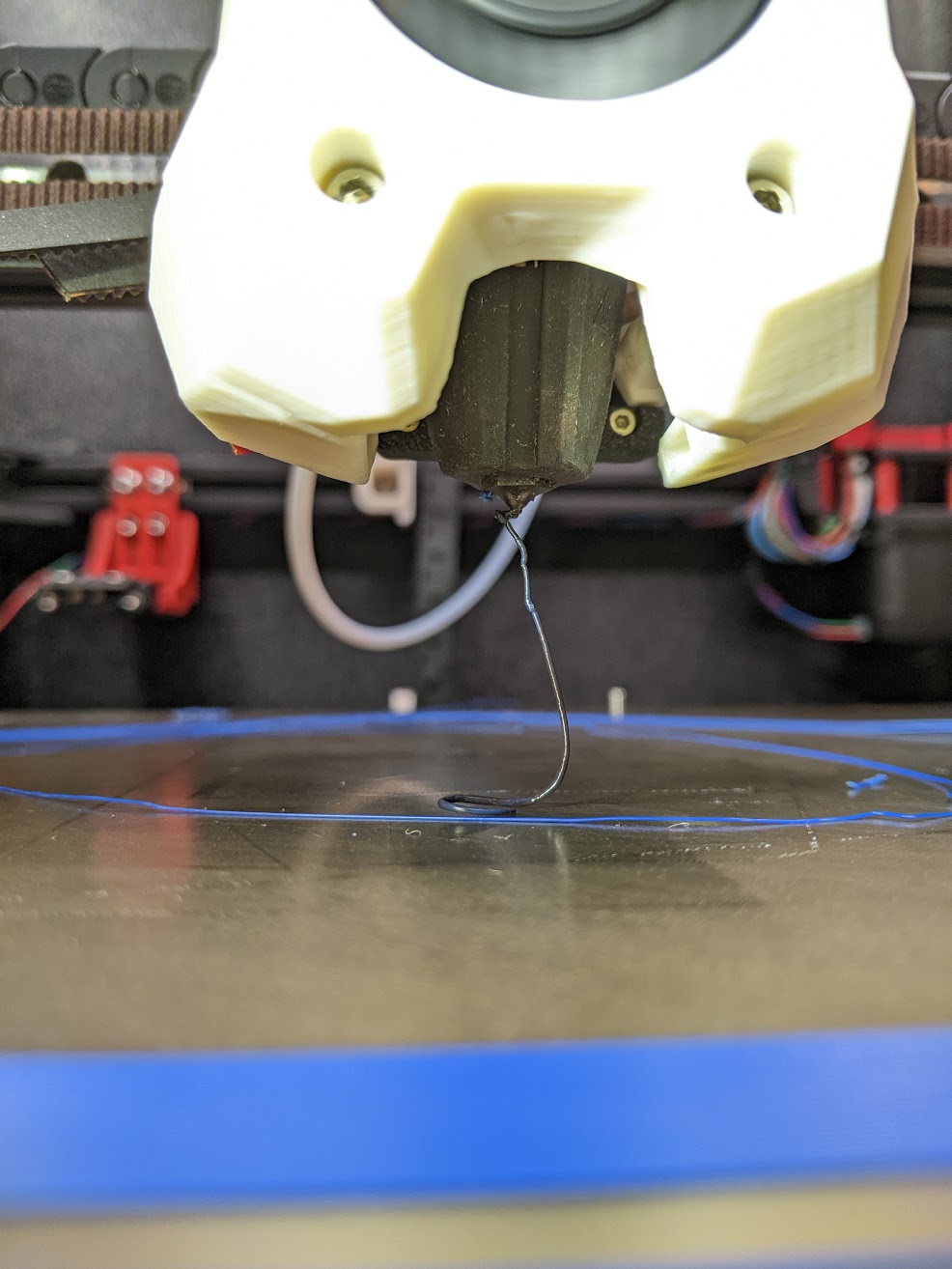

For all three jams, I was able to release the extruder latch and pull the filament out of the heat brake. There was a blob at the bottom of the filament, which would be too big to get through the orifice in the heat brake (it’s a very snug fit on a Rapido). I suspect this is from sitting touching the heat brake for the remaining hour and 50 minutes in the print after the jam occurred. Note to self: install a filament run-out sensor…

There’s also always been a little bit of filament left in the hot end. The photo below is what came out after manually pushing it out with a metal rod I got with my i3 clone.

After the first clog on the small print, I reset and the print went off without a hitch. I didn’t think about it again until the top print above failed. I decided to swap nozzles just to be safe and bumped my extruder temp up from 230 to 240.

It looks like I might have been under extruding a tad on the third print and/or I need to tune pressure advance. The OG nozzle was plated brass, and I had recently tuned, so if it was starting to wear out then some minor under extrusion with a new/fresh nozzle makes sense.

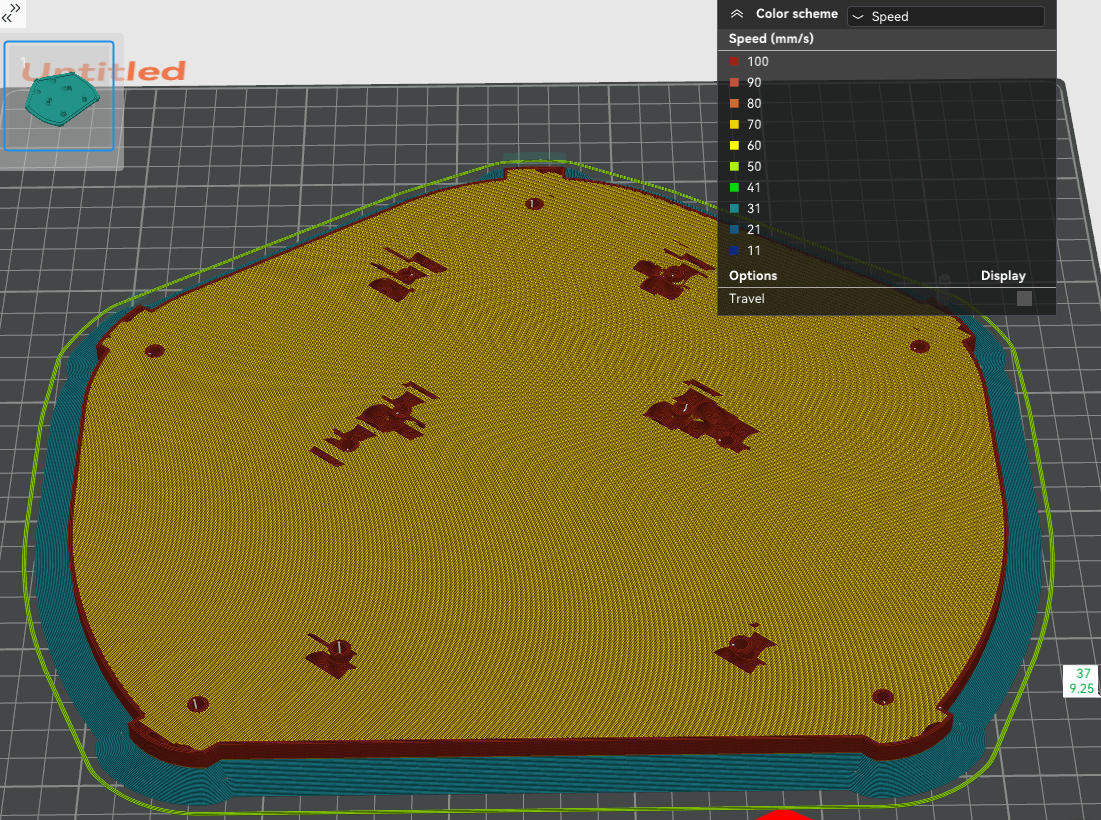

Here’s what the slicer shows as happening on this layer. I am not showing the full layer so you can see it ends with the internal bridge on the lower left. There are a handful of retractions, but they’re not very frequent. There is no retraction at the end of the internal bridge before the travel to the start of the next layer.

The next layer starts perimeters first in the lower right hand corner. I don’t see evidence of the perimeters starting, so odds are the jam is happening between the two layers.

I have the slicer set to print nearly all features at the same speed, other than overhangs. This is potential correlation #1

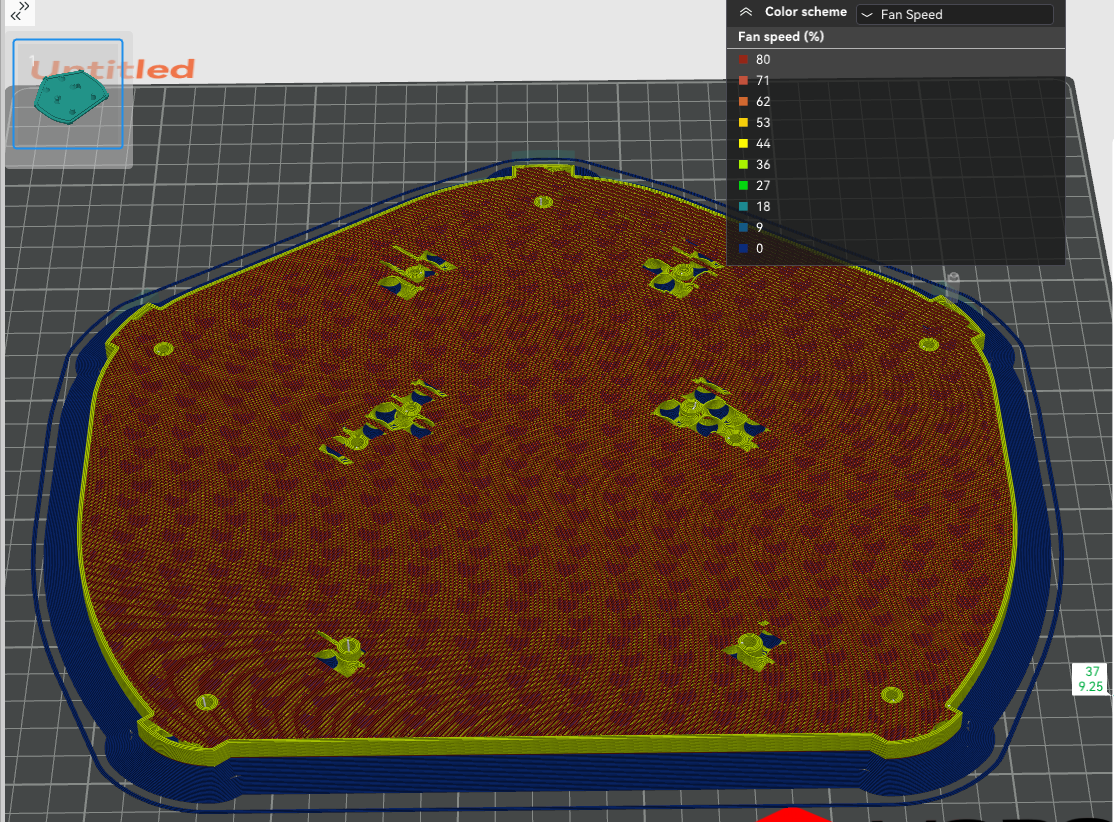

I have the fan set to 40% with no cooling for the first 10 layers. However, for overhangs it’s going to 80%. This is potential correlation #2

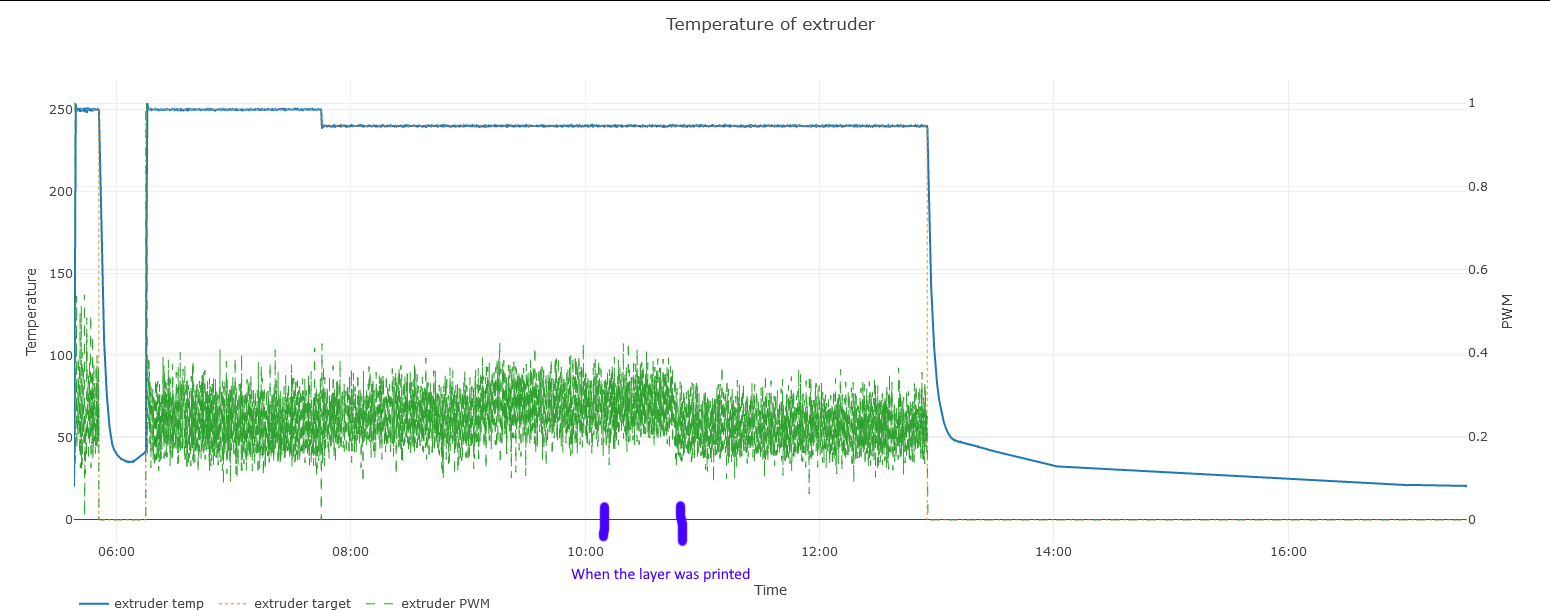

Looking at a graph of what was going on with the extruder, it looks like all is (fairly) well here, at least from a temp perspective. The min PWM value might increase a hair for this layer, but without calculating the average and/or smoothing the line it’s hard to eyeball meaningfully. It does appear that the PWM falls off some once the jam occurs.

All ideas and tips welcome!

If the slicer shows the same holes in the sliced file, it is likely caused by the model itself.

Had the same issue once, kept failing the exact same way no matter how I sliced it.

Ended up recreating the model and then it sliced perfectly without any problem.

If that isn’t an option for you, you can try to fix the model itself. I use MeshMixer for that. You can use this guide for the steps: https://3dprinterly.com/how-to-repair-stl-files-for-3d-printing-meshmixer-blender/

Interesting. I generated the STL from fusion 360 and Orca didn’t say anything about a non-manifold print. The rest of the layers look normal in orca, but maybe I should check a gcode viewer too…

You got an awesome write up I don’t see anything wrong with.

It might just be the filament. I had some reflow that gave me the exact same bulb because it was a little janky. Tossed it and everything was smooth sailing afterwards.

I’m going with this. I have a large spool of a wood color from a manufacturer that I’ve never used and it has only completed 1 print that was small but failed twice before it finished correctly. Not using it again, it’s PLA though.

Thanks! I was really hoping to find a smoking gun going through everything (like lots of retraction, something weird going on with temp, etc) and was somewhat disappointed to not find anything.

Do you think I’m drawing a false correlation with the jam always happening at the same feature type? The first failure was about 25 minutes into a short print on an internal bridge layer and both these failures happened on the exact same layer in basically the same spot?

It doesn’t seem like a filament issue would be impacted by feature type. Random clogs, absolutely.

Sometimes its a physical issue in your setup.

Double check your cable, double check the carriage, and double check the rails, look for potential obstructions.

I had one print that kept failing in the exact same place each time, couldn’t figure it out, then I watched it live and the dang ribbon itself was physically catching on a specific part of the geometry mid print and then the print would twist a bit, lol.

Something to consider, I’d recommend visually watching that specific layer when it’s coming up to see if you see something happen.

I’ll have to babysit the next print, or at least make sure I’m around for the 4 hour mark.

The question is whether I should change anything (speed, cooling) or just to just go as-is.