Damn, it took me a while to get this joke. Well done! :D

- 9 Posts

- 153 Comments

Yup. It’s not as loud and less energy intensive usually.

Hah, I didn’t mention the most important part. It basically switches on a ventilator when the absolute moisture content outside is lower than inside. This results in drying of the room that you ventilate like a basement with moisture issues. The dew-point acts as a proxy for measuring absolute moisture content.

Are you building a C/C++ project that should run on BSD, Gnu/Linux and other platforms? Then maybe use autotools. All distro tooling will easily be able to handle it.

Are you just building some small project that will never make it into a distro, maybe just use something simpler. Or even just a plain makefile.

131·26 days ago

131·26 days agoThings are suspicious but you still spread gossip and maybe lies.

I understand how this could be a prime target of a supply chain attack and that things are a bit fishy. On the other hand people are waaaay less picky about installing other binary blobs on their machines. I wish paranoia would be more general :)

Just use cp instead. No reason to use dd.

661·26 days ago

661·26 days agoNobody knows who responded here. Don’t spread rumors.

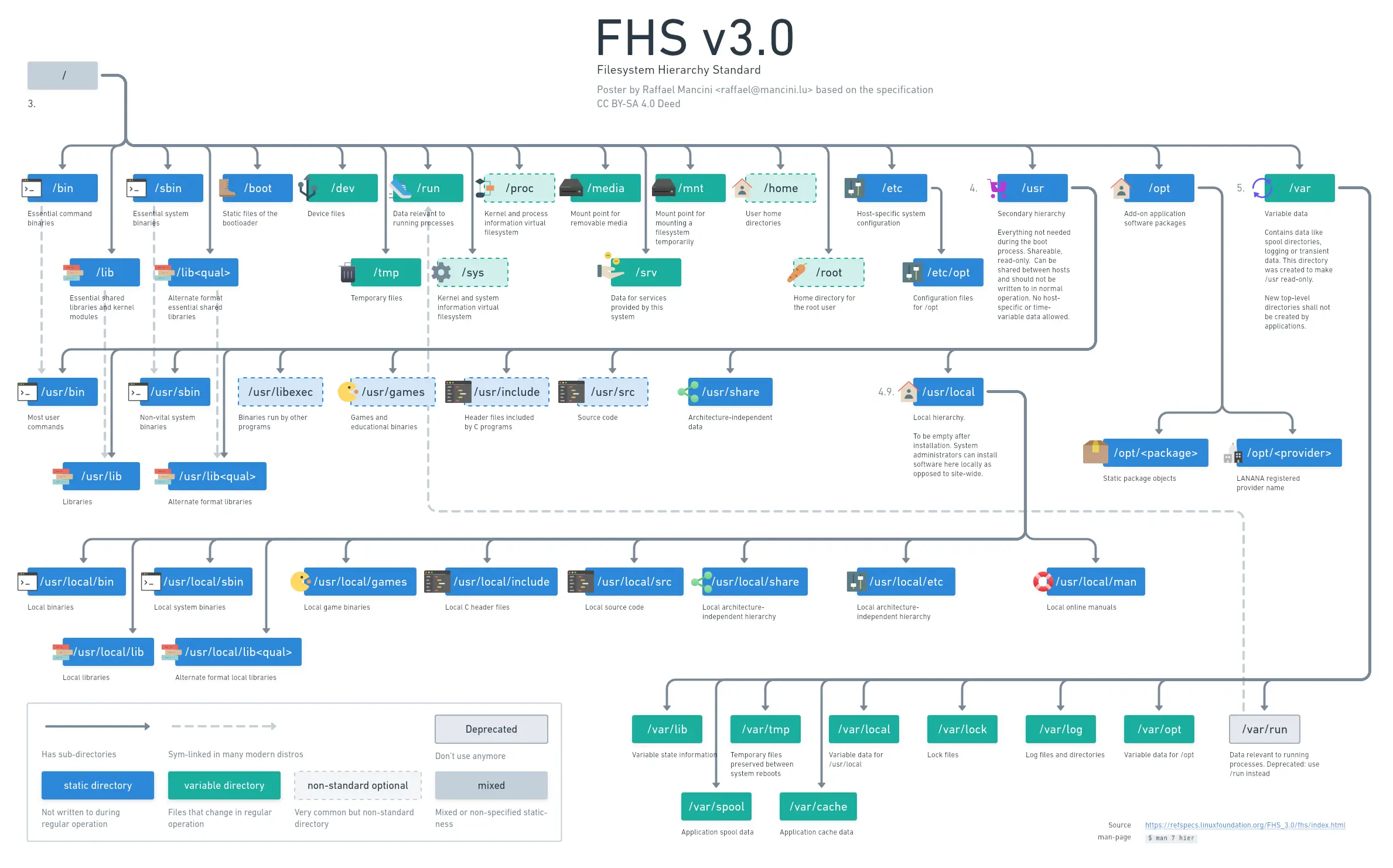

Look at the post behind the link. There is a dark mode version.

https://lemmy.world/post/9437525

My version of this with a bit more detail

1·2 months ago

1·2 months agoDid you measure that? Would be great if it was only fractions of a mm.

2·2 months ago

2·2 months agoWould a larger inner diameter not cause the transmission of movement to be less direct due to bending and coiling inside the tube? This is probably mostly an issue in bowden systems

I’ve been using various GNU/Linux distro over the course of the last 20 years. When I started out, packages could never be too fresh and cutting edge. Nowadays I’m an admin and I administer way too many VMs. I dream of a system that I never need to update. While I know that’s almost impossible if you want to be secure now might finally be the time I give slackware a try. I’m also old enough to be more curious about learning less but more in depth.

Libre office calc would do the trick also, every cell is a day for example

Why a gantt chart for a road trip though. There are not that many parallel things you usually do, no?

Sorry, I completely didn’t read all of your comment. You’re right about resistance but then again the filament won’t need to touch the enclosing coil at a large surface. In the usual bowden tubes, you have a lot of contact surface between tube and filament but this would not need to be the case in the drying coil. In the end it would all depend on the application. I’m not interested in very high speed printing (yet) because my machines are all pretty slow :).

You “just” need a longer distance inside the drying chamber. This could be achieved by coiling up the space where the filament travels through and guide hot and dry air through that space, ideally from the outlet towards the inlet. That air could maybe be pulled from the hotend cooler.

Argh finally someone tries the obvious solution. I was already considering it but was demotivated since it seemed so obvious and nobody seemed to have done it before.

This device could also probably be printed in PLA. I can’t wait until I get my lab power supply so I can give this a try with a wire coil heater.

Edit: you could even mount some PTFE tubing mounted below a heated bed and pass air through it. That way you could potentially get away without a heating element and re-use some power usually lost.

Great project! I would love to see them on someone. I fortunately don’t need glasses but I might at some point consider printing sunglasses.